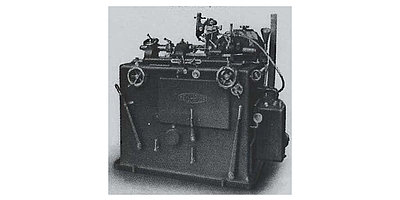

In 1945, the first ever continuous generating grinding machine, called ZA, was put into operation and introduced the „Reishauer Method“ as the process is still often referred to today. In fact, the underlying principle has remained the same to this very day.

An interesting aside worth mentioning is that the thread grinding machines were equipped with gears manufactured by Reishauer. Again, it was the dissatisfaction with the status quo of technology that drove Reishauer’s engineers to develop - or rather to invent - the continuous generating process as they were aiming for a more accurate, faster und cost-effective way of grinding gears. Following an intensive 15-year development time, the new machine was ready for operation in 1945. From this point on, Reishauer’s own gears would no longer be ground tooth gap by tooth gap but with a few passes of this new enveloping continuous generating method. This faster and more accurate method of gear manufacture, the continuous generating grinding, consolidated Reishauer’s reputation worldwide, and started a new chapter of its history, which, even today, keeps shaping the future of the hard-finishing of gears.

The visionary prediction of the ZA brochure of 1945 read as follows:

„In the future, gears will be ground which we cannot grind today due to high costs, even though it would be preferable to do so now“.